Ingénierie

Allier innovation et exigence pour créer des matériaux novateurs dans une solution appropriée à vos besoins.

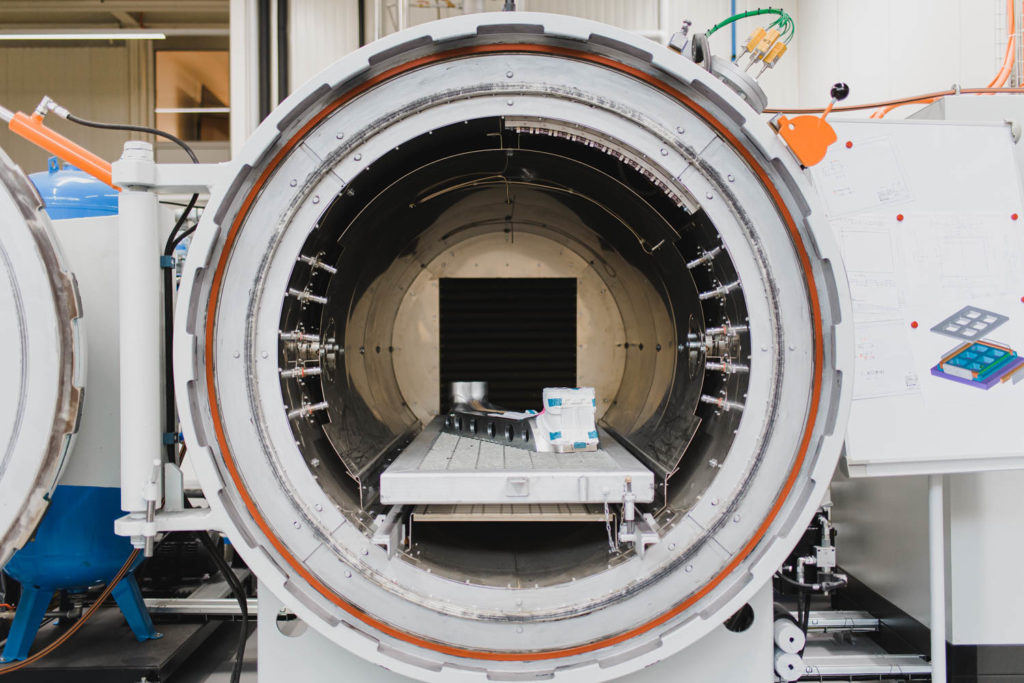

DécouvrirFabrication composites

Lier les compétences humaines aux performances de la machine pour permettre aux matériaux composites de prendre une forme adaptée et cohérente.

DécouvrirFabrication additive

La création de formes et de surfaces permet de marier flexibilité et maîtrise des coûts en toute liberté.

DécouvrirManagement et assurance qualité

Maîtriser les processus et gérer les risques tout en restant fidèles aux valeurs d’innovation et d’humanisme de l’entreprise.

DécouvrirEntreprise

En 1988, l’entreprise Busch fait paraître une annonce dans le journal : elle recherche activement un « pionnier en matériaux composites » …

DécouvrirHistoire

En 1988, l’entreprise Busch fait paraître une annonce dans le journal qui dit qu’elle recherche activement un «pionnier en matériaux composites» ...

Découvrir