Aerospace & Mobility

Materials that contribute to human progress, taking us higher and further.

Find outENGINEERING

Combining innovation and high requirementsstandards to create innovative materials for solutions appropriate to your needs.

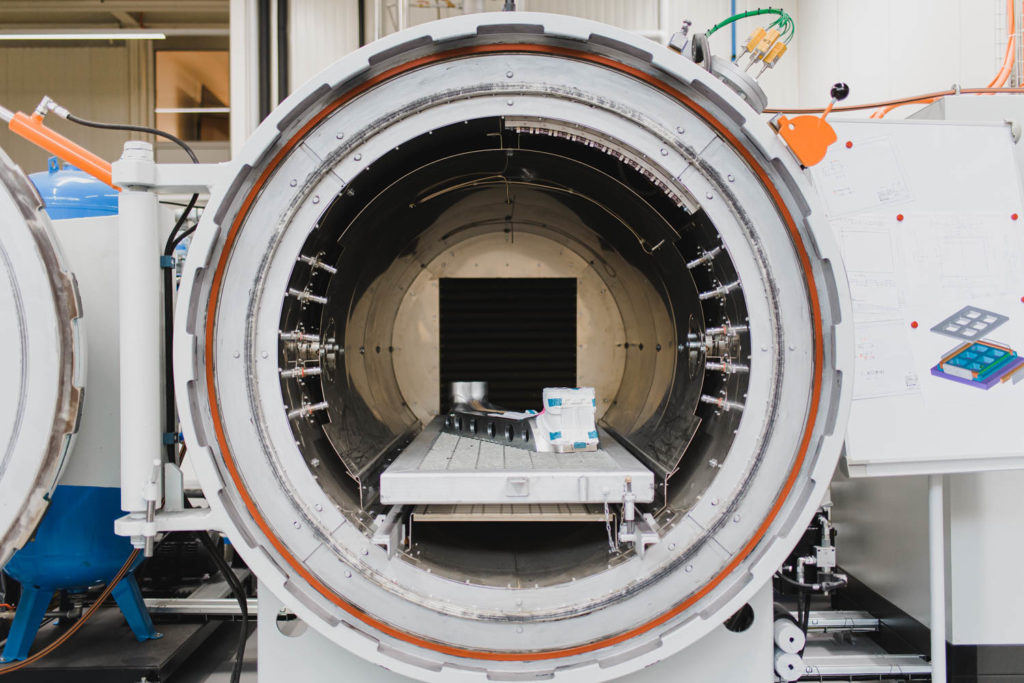

Find outComposites Manufacturing

Harmonising human expertise with machine precision to shape composite materials into suitable, coherent forms.

Find outADDITIVE MANUFACTURING

Unlocking the potential combining flexibility and cost-effectiveness for total freedom in shapes and surfaces.

Find outQUALITY MANAGEMENT AND ASSURANCE

Overseeing processes and managing risks while remaining true to the company’s values of innovation and humanism.

Find out